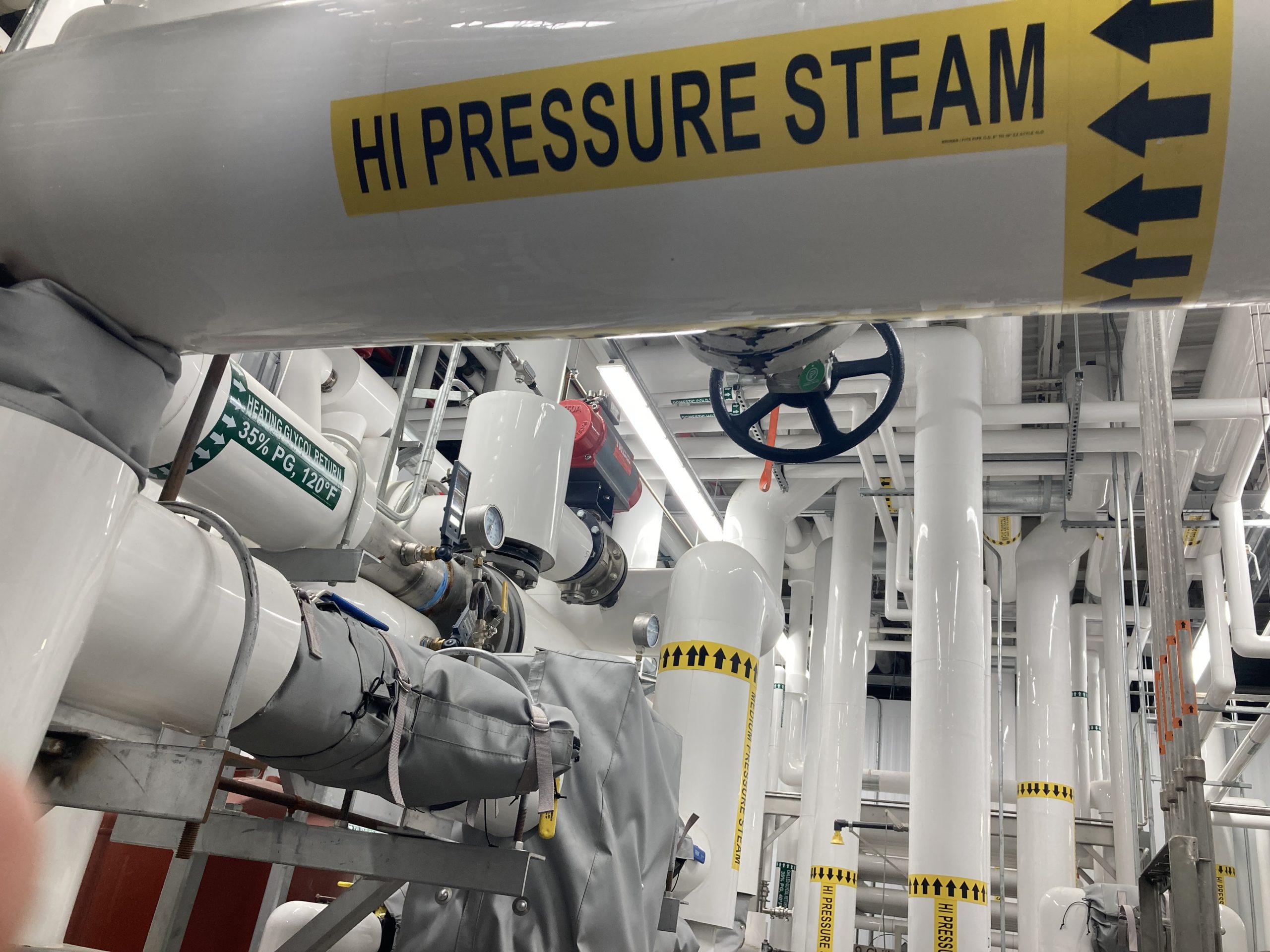

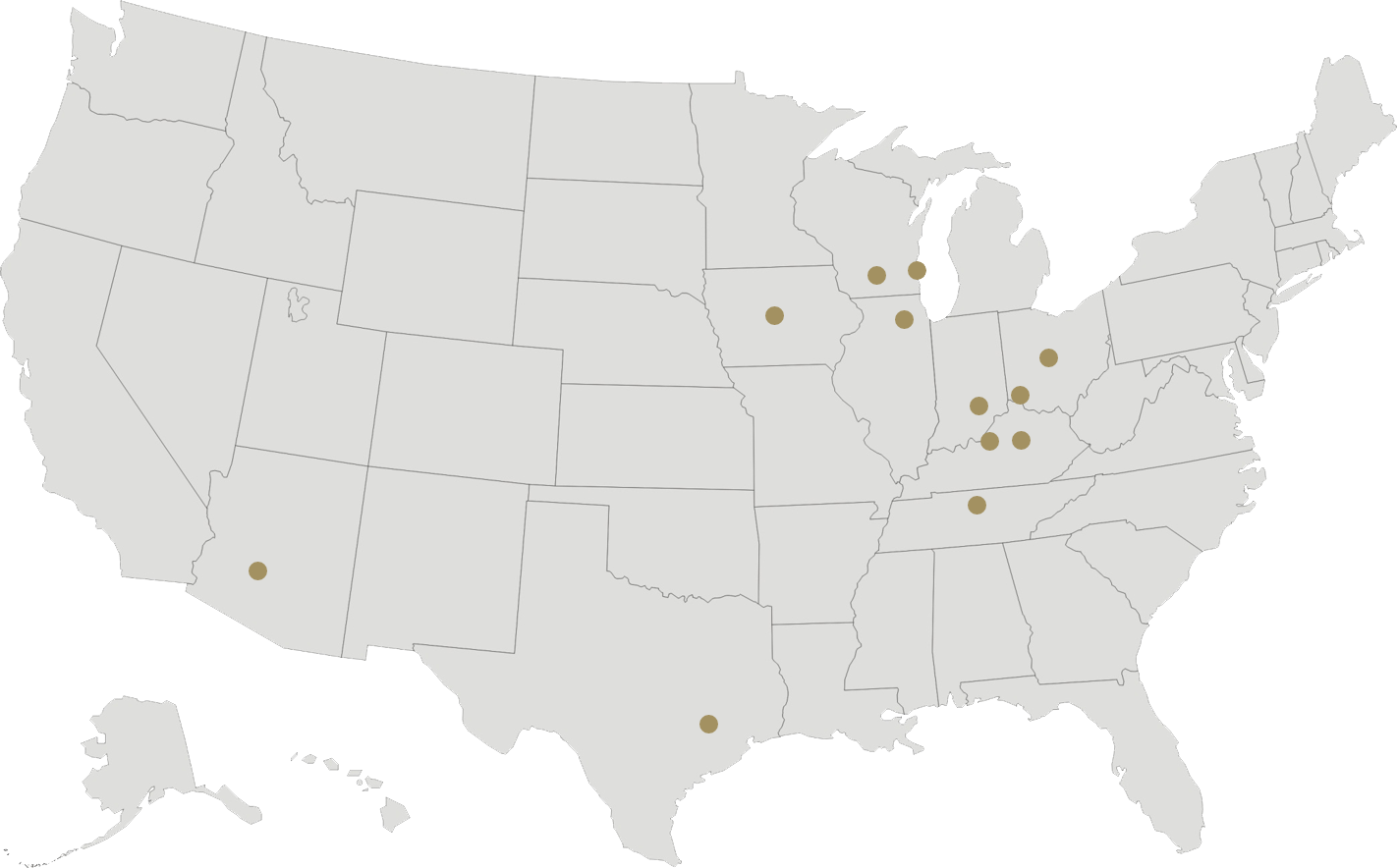

We assisted our client with facility utility system additions and modifications for a new production line in an existing food production plant. Phased construction planning was critical for implementation of this new line while existing production continued in surrounding spaces. Structural and architectural modifications were required including demolition and addition of floors, walls, ceiling, and platforms. Piping system modifications included plumbing, fire protection, steam, condensate, compressed air, chilled water and refrigeration systems. Hygienic HVAC systems were added and a new electrical services was designed for the additional power requirements.

Back to Project GalleryProjects